On-site inference flags disease and pest indicators early, enabling faster interventions and reducing batch variability without increasing manual scouting overhead.

Verdant Helix offers a comprehensive portfolio of services for medicinal cannabis producers. From facility design to ongoing analytics, we help you build and operate a highly efficient, compliant and scalable operation. Below is an overview of what we provide.

Blueprint-to-build delivery: HVAC zoning, airflow strategy, sensor placement, and clean workflow layout for compliant operations.

We design and implement customised growing facilities. Our team handles layout, environmental systems, workflow optimisation and integration with automation technologies. We collaborate with architects and engineers to ensure compliance with local regulations.

Typical budget: €500k – €2M

Repeatable robotics: picking, pruning and task automation with safety envelopes, toolpaths and audit-ready action logs.

We deploy robotics and automation for seeding, transplanting, nutrient dosing, irrigation and climate control. Our solutions reduce labour costs and increase consistency.

Custom pricing

Computer vision + edge inference: stress scoring, disease indicators, canopy metrics and alerts—without exposing sensitive facility data.

Our computer vision systems monitor plant health, detect pests and diseases early and provide recommendations for pruning and harvesting. AI models learn from your data to continuously improve predictions.

From €30k per module

Seed-to-sale traceability: time-stamped events, environmental history, batch lineage and evidence exports for audits and QA.

We implement digital traceability systems that record every step of the cultivation process from seed to sale, ensuring full compliance with medical regulations and quality standards.

Subscription available

Operational ramp-up: training playbooks, SOPs, KPI dashboards and continuous optimisation to reach stable, repeatable production.

Our team provides training for your staff on new systems and ongoing support to keep your facility operating smoothly. We offer remote monitoring and maintenance packages.

Hourly or annual contracts

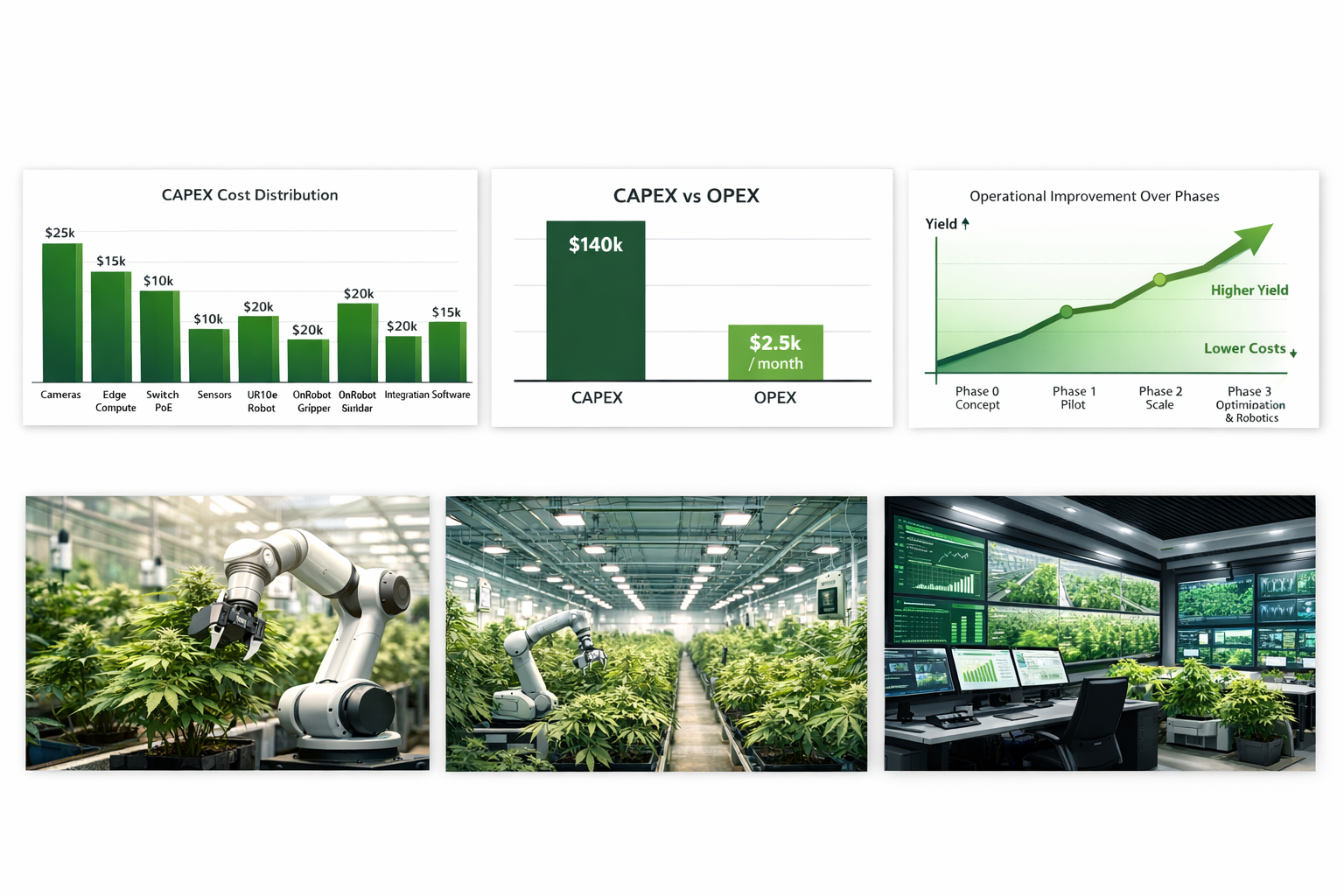

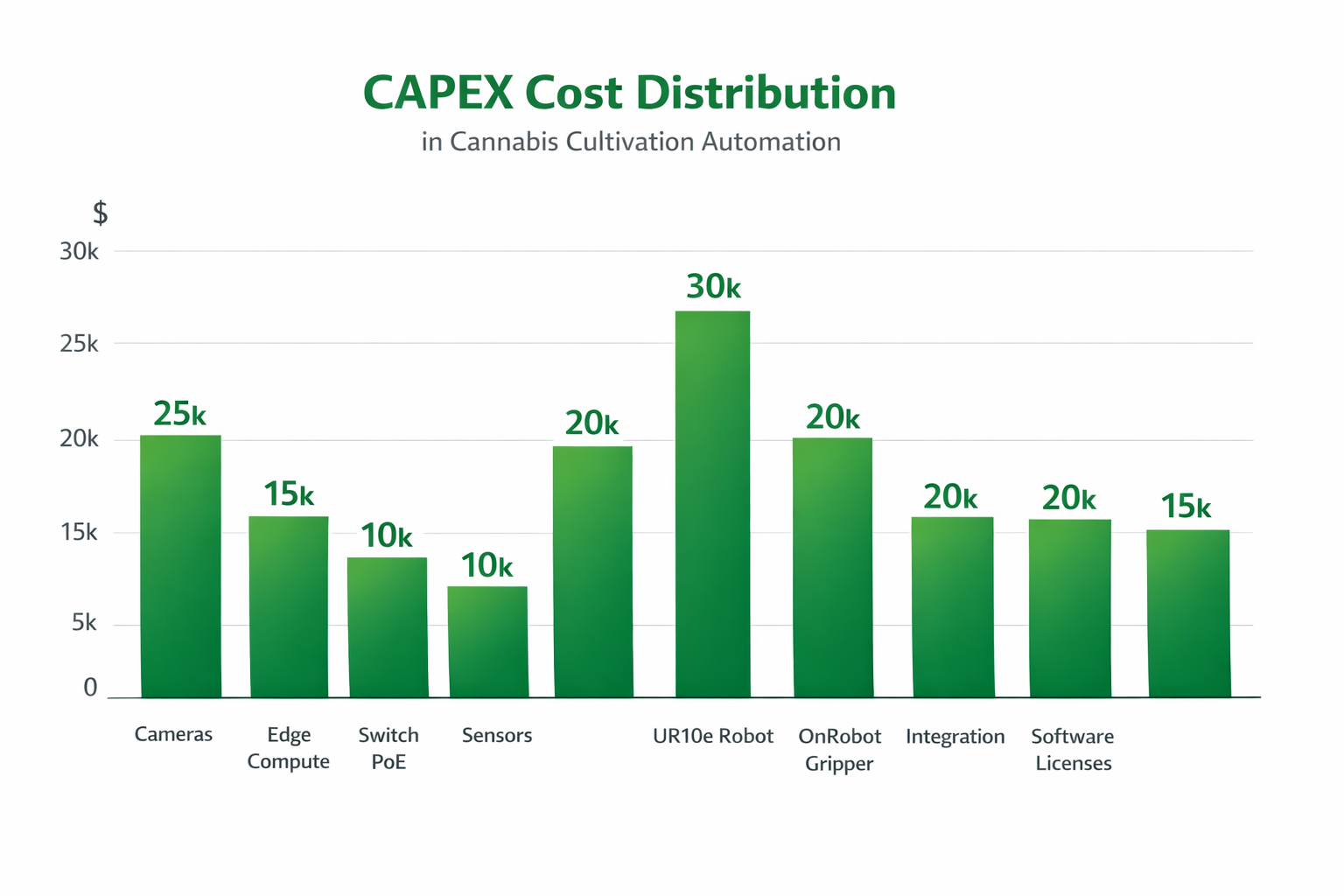

A representative capital expenditure breakdown across key categories is shown below. Each bar reflects an indicative budget allocation for components such as cameras, edge computing, networking equipment, sensors, robotics, integration services and software licences.

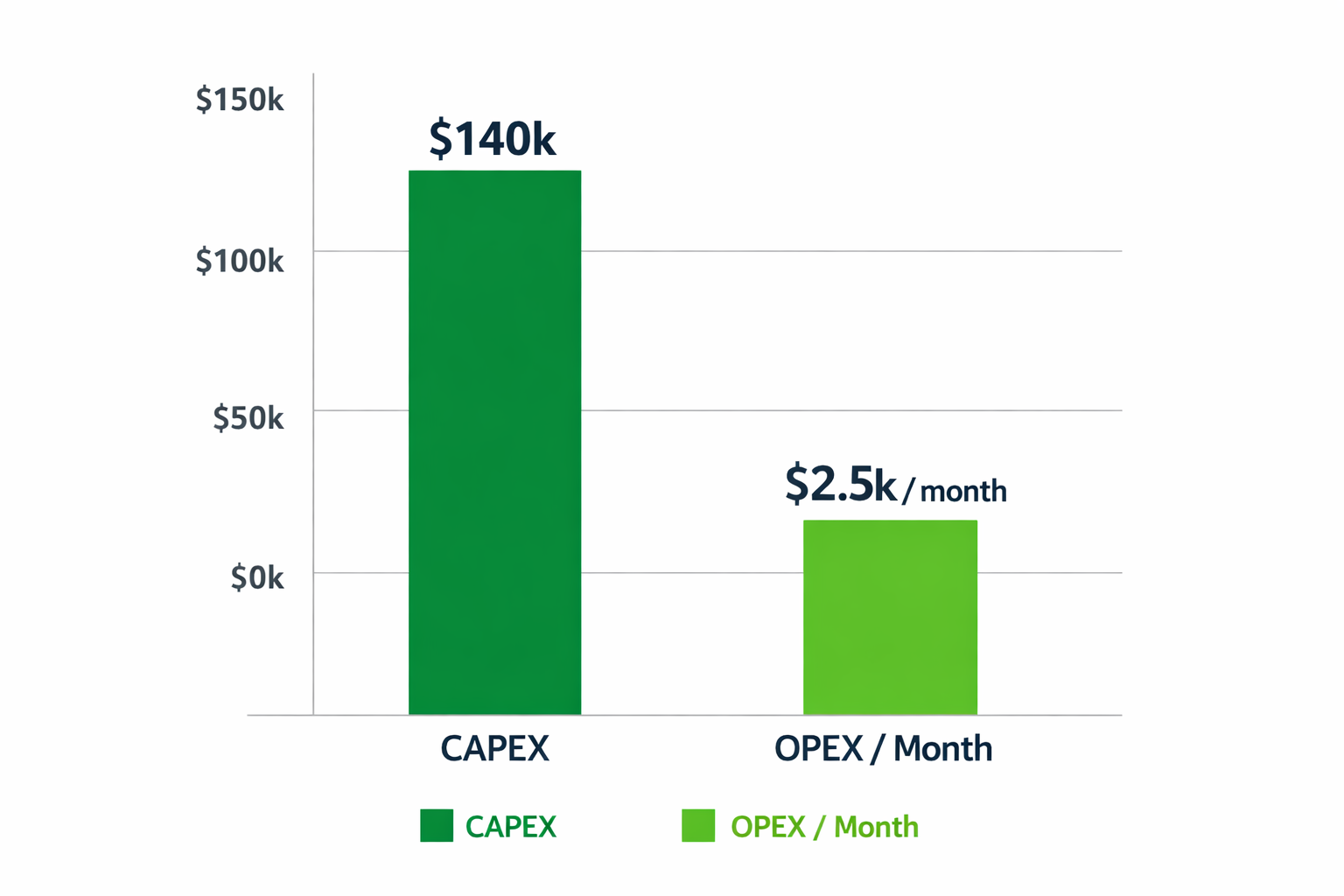

Our solutions typically involve an upfront investment (CAPEX) followed by ongoing monthly operational expenditure (OPEX) for maintenance, support and cloud services. The graph below compares the total CAPEX with typical OPEX.

Below are illustrative examples of how we combine perception (cameras), decision intelligence (AI models) and execution (automation/robotics) to deliver measurable operational outcomes.

On-site inference flags disease and pest indicators early, enabling faster interventions and reducing batch variability without increasing manual scouting overhead.

Robotic handling supports consistent operations across shifts, improves ergonomics, and helps facilities meet quality targets through standardised processes.