Models triage plant-level events (healthy / suspected issue) and schedule the correct action (robotic inspection, manual QA, or process adjustment). Every decision is logged with confidence and traceability.

Verdant Helix leads the industry in applying artificial intelligence and automation to medicinal cannabis cultivation. Our solutions are designed to adapt to your unique facility and growing conditions, increasing yields and reducing costs.

Our imaging systems use high‑resolution cameras to monitor every plant in real time. Advanced machine learning models analyse these images to detect nutrient deficiencies, pest infestations and signs of stress long before they become visible to the naked eye. This allows growers to intervene early and prevent losses.

Using historical data and environmental sensor inputs, we build predictive models that forecast yield outcomes, ideal harvest windows and resource needs. These insights help growers plan operations more effectively and optimise profits.

Our robotics portfolio includes autonomous systems for moving trays, transporting plants, precise trimming and even gentle harvesting. Robots work alongside human staff to handle repetitive tasks, free up skilled labour and maintain a controlled environment.

We provide a unified software platform that centralises all data streams—from sensors and cameras to robotics and climate control. Users can view dashboards, manage workflows and receive alerts from any device. APIs allow integration with third‑party software and ERP systems.

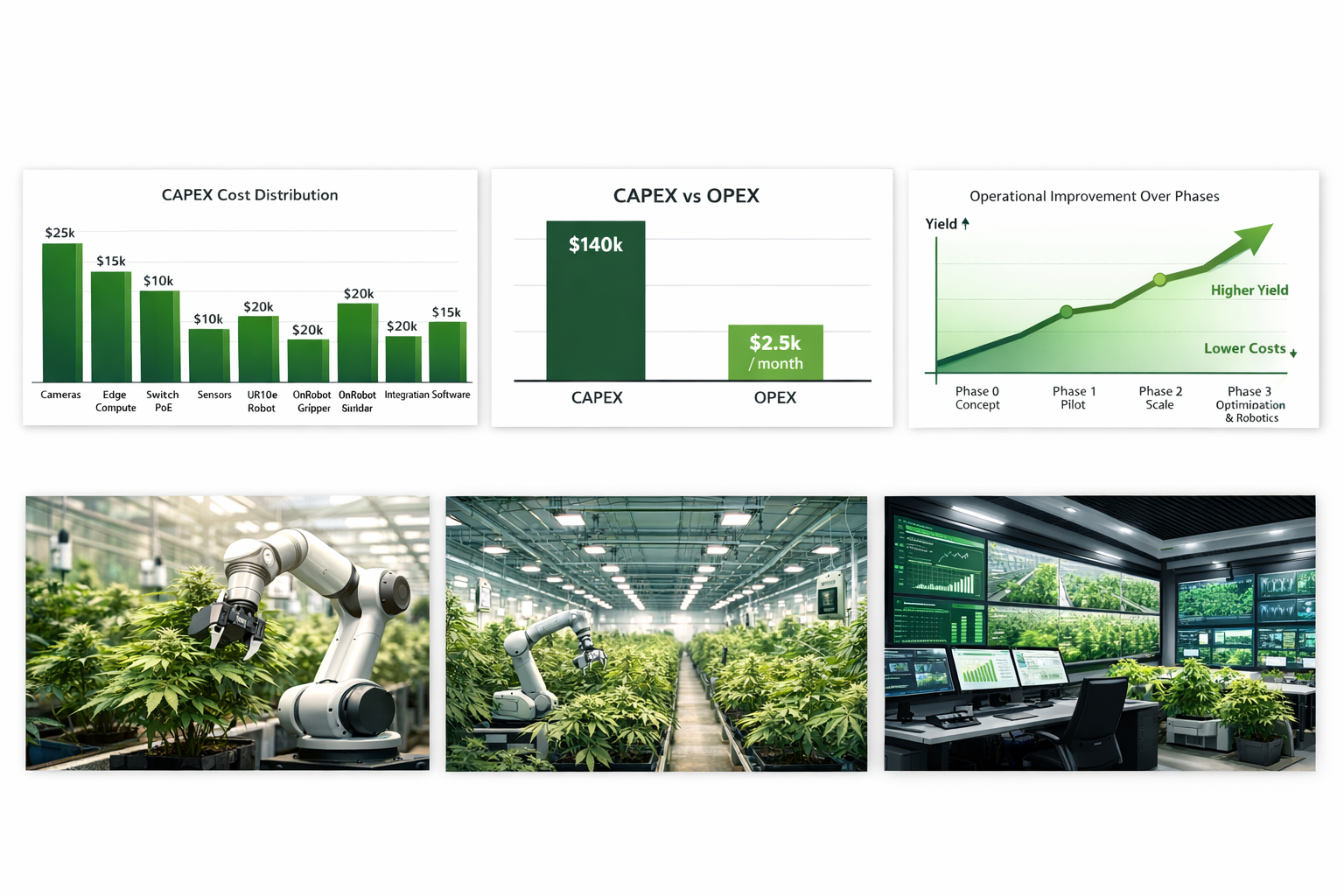

Intelligent automation delivers compounding benefits over time. The graph below depicts how yields increase and costs decrease across project phases.

Our delivery model focuses on a closed‑loop workflow: cameras → AI inference → decision engine → robotics / SOP tasks → audit logs. This makes performance measurable, reproducible and compliant.

Models triage plant-level events (healthy / suspected issue) and schedule the correct action (robotic inspection, manual QA, or process adjustment). Every decision is logged with confidence and traceability.

A single operational view: yield forecasts, batch lineage, environmental stability, and intervention history—built to support regulated medicinal workflows and continuous improvement.